Tweet/Garot

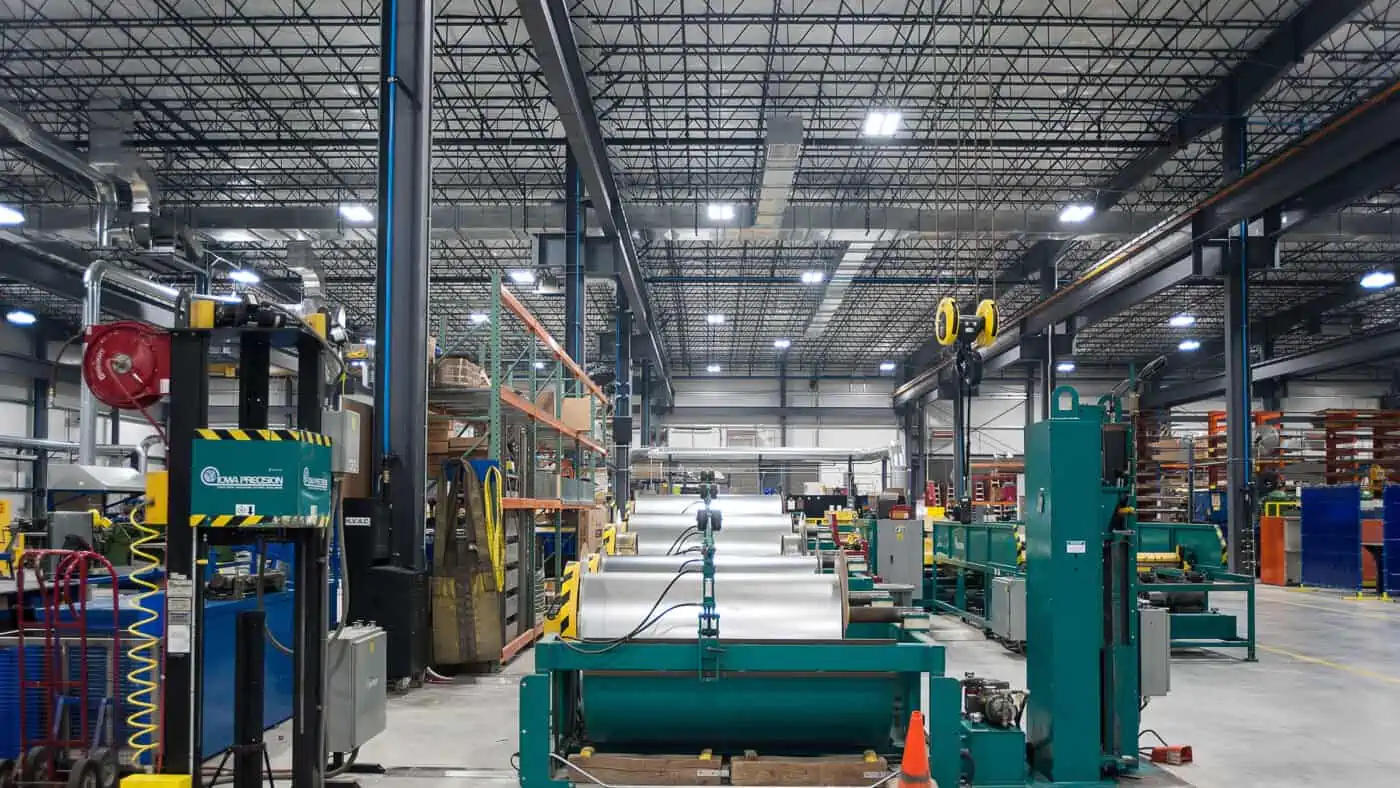

Tweet/Garot needed to centralize its piping fabrication, plumbing fabrication, sheet metal fabrication and tooling into one facility. This provides the opportunity to innovate around collaborative workflows and processes to increase efficiency and speed up production. The size and flexibility of the facility is directly related to the Tweet/Garot team’s philosophy of continuously improving, reducing lead times and eliminating waste from its value stream. This integrated design-make model required a collaborative and adaptable environment to create faster, flexible workflows that produce consistent, standardized, quality products.

In addition, the facility has a 4,000 SF office space to serve as the primary location for office employees directly involved with the manufacturing process. The office area has a large break area, restrooms and a balcony area that has been set aside for future expansion and mechanical equipment.

Tweet/Garot

Wrightstown, Wisconsin

Boldt Technical Services

- Design-Build

- Construction Manager

- General Contractor

New Construction

39,000 SF

Project Highlights

- As the construction was progressing, the owner was still adjusting the flow of operations, including final equipment placement. MEP rough-in locations needed to be determined early in the construction phases to eliminate rework. This was accomplished with multiple visits by MEP contractors to determine electrical and mechanical requirements of the equipment being relocated into the new manufacturing space. Constant communication between the owner, CM and MEP trades took place to discuss these challenges and complete the work correctly the first time.